|

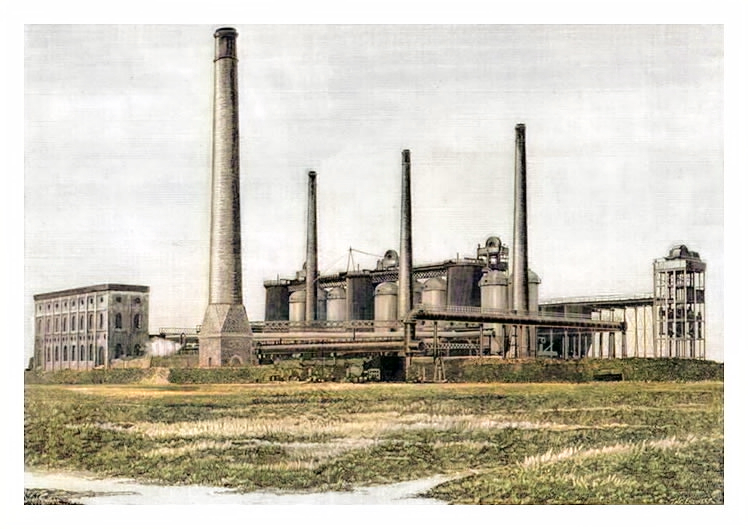

The construction of the blast furnaces at East Moors Iron and Steel Works is almost complete in this (colourised) photograph [048] [049] taken about 1889. The works opened in 1891 and was nicknamed "Dowlais-by-the-Sea" since it challenged the works at Merthyr in the Rhondda. Bradshaw [047] in his railway guide of 1866 stated that the population of Cardiff was 32,954 whereas Merthyr was 83,875. He recounts that "The largest works are those belonging to Lady Guest and Messrs. Crawshay, where 3,000 to 5,000 hands are employed. At Guest's Dowlais works there are 18 or 20 blast furnaces . . . and 1,000 tons of coal a day are consumed. Visitors should see the furnaces by night, when the red glare of the flames produces an uncommonly striking effect." I recall the rich red sky above Dowlais-by-the Sea as a child. |

| |

|

The lithographic plate (colourised) from the 'Engineer' [periodical published in November 1891 entitled 'Blast Furnaces at the Dowlais-Cardiff Steel Works - Steel Works, Cardiff - North-East View']. [015] [016]

Arnold Karthaus Reese, B.S., E.M. was manager of Dowlais Cardiff Steel Works, Guest, Keen & Nettlefolds, Cardiff, Wales and resided at The Red House, Victoria Road, Penarth, Wales according to the Alumni and Students of Lehigh University, South Bethlehem, Pennsylvania of December 1912. [499] [503]

|

| |

|

In the early 1970's I returned to south Wales for a few months and worked for a time as a shift engineering fitter on the steel rolling mills of the Castle Works of GKN, Guest, Keen and Nettlefolds which was situated on the Cardiff docklands, nearby "Tiger Bay". Steel ingots were brought directly from the Dowlais steel works next door for hot rolling into sections such as concrete reinforcement "rebar" which were still red hot and traveling at around 60 miles per hour by the time they reached the end of the mill. I colourised the above image just to add a little sense of the danger experienced by workers at the works.

The image dates from August 1960 and is of the continuous rolling mill and its double ended layout. As the steel was rolled by being passed through successive sets of rollers, the section becomes reduced but the linear speed of rolling increases. If one of the sets of rollers was not at the correct speed a "cobble" occurred which usually results in red hot steel shooting upwards. On my first nightshift there, I witnessed an accident when the roller-man lost his arm as a cobble landed on him. Only a little blood and just the hint of a good kebab cooking!

The plant was showing its vintage when I worked there since the hot-rolling mill had been installed c.1935 by the Morgan Company of America. It was one of the first rod mills in the UK where the rod was guided without the need for operators using tongs by hand - this being a rather more dangerous adventure altogether!

A new mill was under construction which had twice the capacity and speed and I was earmarked for employment there when I got the call to return to the West Riding of Yorkshire and play soprano cornet with the John Foster and Sons, Black Dyke Mills Brass Band in Queensbury. So no more steel just blowing my own trumpet and maintaining yarn winding machines for making high quality cloth - it was like walking back 100 years!

|

| |

|

|

Guest Keen & Nettlefolds (South Wales) Limited, Castle Works, Cardiff. An advertisement published within the Board of Trade Journal - [1107] [499] 10th January 1958. |

|